Description

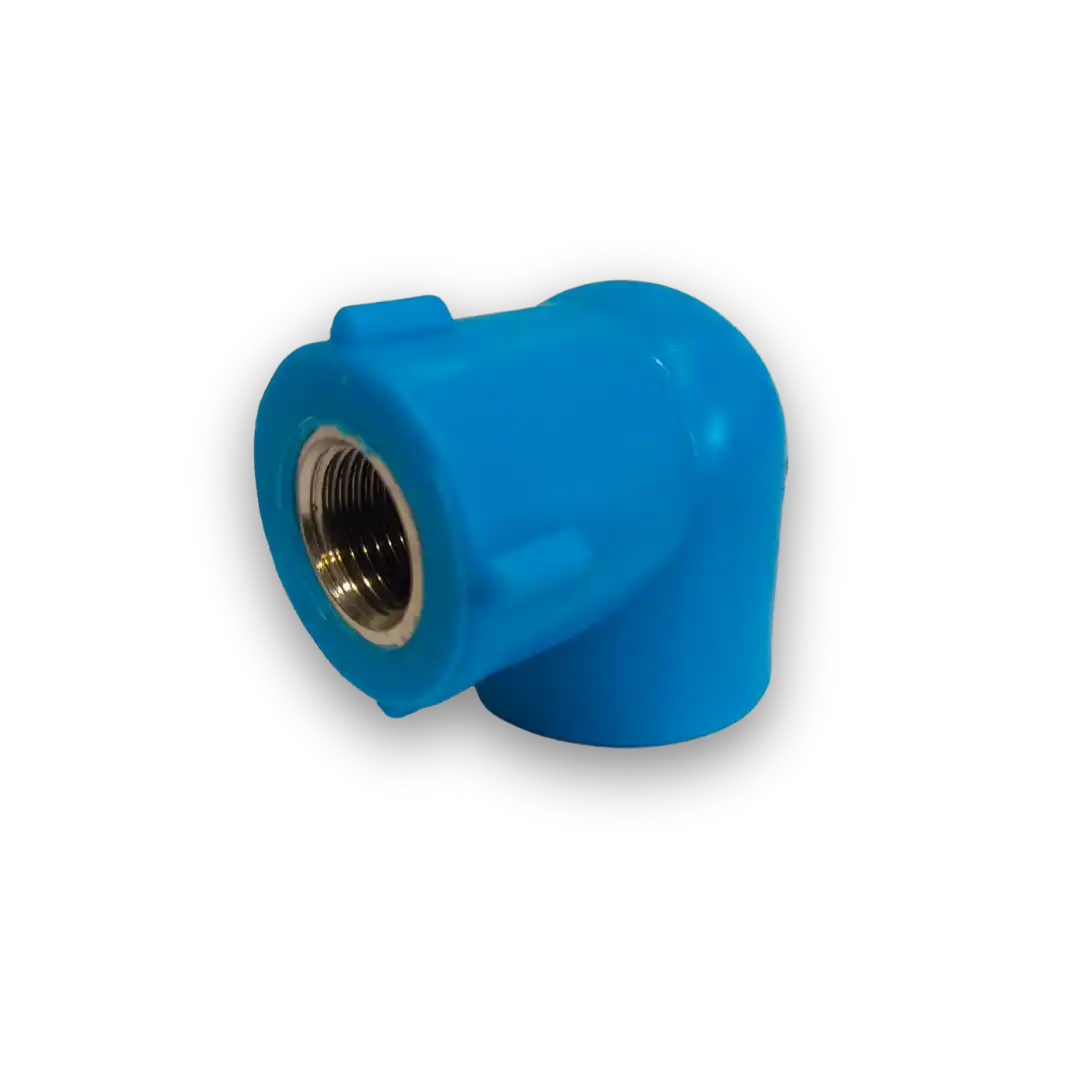

The PPR Female Threaded Elbow (FTE) is a highly durable and efficient pipe fitting designed to create a 90-degree turn in PPR (Polypropylene Random Copolymer) piping systems, while connecting seamlessly to metal components through its female threaded end. This fitting combines the strength of PPR material with a reliable metal female threaded connection, making it an ideal choice for plumbing systems that require transitions between different materials.

This PPR FTE is engineered for use in hot and cold water systems, providing exceptional resistance to high temperatures, pressure, and chemical exposure. Its corrosion-resistant properties ensure that the elbow remains intact and functional, even in harsh environments. Whether you are working on residential plumbing, commercial systems, or industrial piping projects, this fitting guarantees a secure and leak-proof connection that can withstand demanding conditions.

One of the main advantages of the PPR Female Threaded Elbow is its ability to facilitate sharp 90-degree turns in tight spaces, ensuring efficient water flow and optimal system design. The PPR side of the fitting can be heat-fused to PPR pipes, creating a permanent, leak-free joint, while the metal female threaded end securely connects to metal pipes, valves, or other components. This allows for easy disassembly and maintenance without compromising the integrity of the system.

The PPR FTE is available in various sizes to accommodate different pipe diameters, offering flexibility for diverse plumbing configurations. Its installation process is simple, and it requires minimal maintenance over time, reducing labor costs and ensuring long-term efficiency. Additionally, the smooth internal surface of the PPR material minimizes friction loss, ensuring optimal water flow.

Made from eco-friendly, non-toxic materials, the PPR Female Threaded Elbow is safe for use in potable water systems, ensuring the highest water quality standards. Its robust design and high performance make it the perfect solution for plumbing systems that require a secure, leak-proof connection at 90-degree angles.

Reviews

There are no reviews yet.